LUCOEX: Large Underground Concept Experiments

LUCOEX was a four-year project aimed at demonstrating in situ the technical feasibility for safe and reliable construction, manufacturing, disposal and repository sealing methods. LUCOEX examined four repository concepts – horizontal disposal of waste packages in Opalinus Clay; horizontal disposal of waste packages in Callovo-Oxfordian clay; horizontal disposal of waste packages in crystalline hard rock; and vertical disposal of waste packages in crystalline hard rock.

Overview

Project Dates: 01/01/2011 – 31/08/2015

Project Status: Finished

Project Website: http://www.lucoex.eu/index.html (now taken down)

The LUCOEX project executed four parallel proof-of-concept installations at different underground research laboratories which were designed specifically for this purpose. Each experiment focused on different concepts and different geological and technical/legal pre-conditions and all experiments were executed with a focus on openness and willingness to share the knowledge gained to support the development of safe and reliable repositories throughout Europe.

The laboratories were located in:

- Switzerland (a full-scale, multiple heater test in Opalinus Clay at the Mont Terri facility);

- France (a complete high level waste (HLW) cell in Callovo-Oxfordian clay at the Bure facility);

- Sweden (feasibility of the KBS-3H concept in crystalline rock at the Äspö Hard Rock Laboratory (HRL)); and

- Finland (feasibility of emplacing buffer components in the KBS-3V concept in crystalline rock at the Onkalo underground rock characterisation facility).

The LUCOEX project successfully demonstrated that the construction of galleries, manufacturing of buffer components and installation and sealing of galleries can be made to meet the initial state. Much experience was gained during the excavation, installation and sealing stages of the experiments which has provided valuable insights into the future development of safe and reliable repositories throughout Europe.

Objective

LUCOEX aimed to provide proof-of-concept for four different emplacement concepts with the goal to understand and compare important parameters for the implementation and the long-term safety of the concepts. The four key technical areas addressed were:

- Gallery construction.

- Manufacture and emplacement of buffer around waste canisters.

- Emplacement of waste packages.

- Backfilling and sealing of galleries.

Six work packages formed the LUCOEX project, as described below.

Work package 1 – Co-ordination and integration

Work package (WP) 1 was responsible for project management, co-ordination and integration between the different workpackages.

Work package 2 – Full-scale emplacement experiment (FE) at Mont Terri

The WP2 experiment aimed to confirm the suitability of the repository concept in Opalinus Clay by construction of an emplacement tunnel in the Mont Terri HRL, manufacture of bentonite buffer units, manufacture of test equipment for waste and buffer emplacement and demonstration of installation performance.

Work package 3 – Full-scale emplacement experiment at Bure

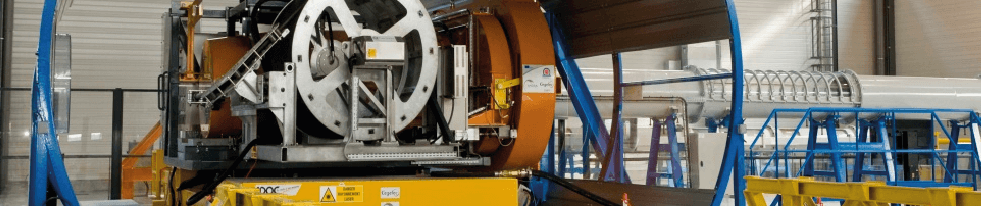

The WP3 experiment aimed to confirm the suitability of the repository concept in Callovo-Oxfordian claystone by construction of an emplacement cell in the Bure HRL, construction of different equipment, construction of end steel plug and shield steel plug, demonstration that the casing may absorb thermal dilation, recording of data on casing behaviour under actual thermal loading and demonstration that the design of the cell head limits thermal gradients on the drift wall.

Work package 4 – KBS-3H at Äspö

WP4 aimed to confirm the suitability of the horizontal repository concept based on SKB’s KBS-3 concept by manufacture of full-scale buffer components, supercontainer and plug components, and installation and monitoring of the system’s initial behaviour at the Äspö HRL in Sweden.

Work package 5 – KBS-3V emplacement tests at Onkalo

The aim of WP5 was to confirm the suitability of the KBS-3 repository concept in crystalline rock by further development and demonstration of the emplacement of full-scale bentonite buffer components in deposition holes, development of quality assurance methods for this, and development of problem handling procedures during installation. Installation was done at the Onkalo repository site in Finland. Short video of this work is available below.

Work package 6 – Management and dissemination

Management of external communications (newsletters, reports to the EC, and so on) was carried out under WP6.