ESDRED: Engineering Studies and Demonstrations of Repository Designs

The Engineering Studies and Demonstrations of Repository Designs (ESDRED) project was a joint research and development effort by major national radioactive waste management agencies and research organisations. The main focus was on demonstrating, at an industrial scale, a number of activities related to the construction, operation and closure of a deep geological repository for high level radioactive waste.

Overview

Project Dates: 01/02/2004 – 31/01/2009

Project Status: Closed

Website: https://www.esdred.info/ (now taken down)

Implementing a geological disposal facility presents a number of unique engineering challenges including the construction and emplacement of the buffer material around high-level waste packages, the transfer and emplacement of waste packages, and temporary sealing technologies.

The ESDRED project was a five year research effort focused on demonstrating the technical feasibility of a number of activities related to the construction, operation and closure of a deep geological repository for high level radioactive waste.

The project successfully demonstrated a number of technologies at a large scale, showing the technical feasibility of the industrial-scale implementation of various buffer, emplacement and sealing systems. The ESDRED project also organised a number of training and communication activities to increase public and professional knowledge about radioactive waste disposal.

Objective

The ESDRED project had three specific objectives:

- The First ESDRED objective was to demonstrate, at an industrial scale, the technical feasibility of some very specific activities related to the construction, operation and closure of a deep geological repository for high level radioactive waste. This was executed through four technical modules:

- Module 1 Buffer Construction Technologies for Horizontal Disposal Concepts

- Module 2 Transfer and Emplacement of Waste Canisters

- Module 3 Heavy Load Emplacement Technology

- Module 4 Temporary Sealing (using low-pH cement) Technology

- The Second ESDRED objective was to promote a shared European vision in the field of radioactive waste disposal technology.

- The Third ESDRED objective was focused on training and communication. This objective was directly addressed in Module 5 (training and communication). The sub-objectives of this module were:

- Training of students, engineers, and personnel from radioactive waste management agencies and R&D organisations.

- Dissemination of ESDRED results to the professional community directly and indirectly related to nuclear waste management.

- Dissemination of results to the public at large.

- Motivation of students towards an interest in radioactive waste programs.

- Confidence building.

Results

The first objective of the ESDRED project comprised a large technical programme addressing a number of the issues related to geological disposal. The technical achievements of the ESDRED project against each of the project modules were as follows:

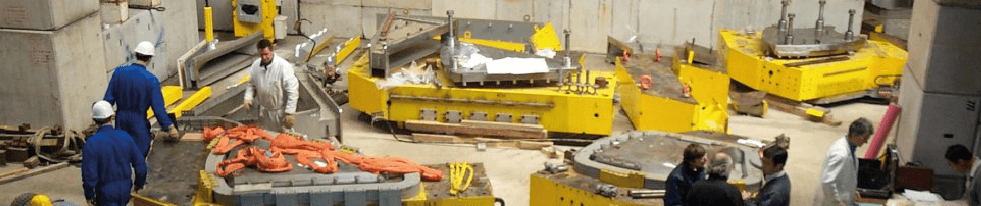

- Module 1, Buffer Construction Technologies for Horizontal Disposal Concepts: A number of experiments were undertaken which developed, tested or demonstrated buffer construction technologies. The technical achievements of module 1 were:

- The development of a cold compaction technique for an MX-80 bentonite/quartz sand mixture to create prefabricated buffer rings.

- The demonstration of the feasibility of two different emplacement techniques for backfilling the annular voids around a horizontally disposed of high level waste package.

- Testing of the emplacement of a range of bimodal mixtures of granular bentonite using a reduced-scale steel model of a horizontal disposal drift.

- Performance tests on four seals of different clay/sand composition in boreholes at the Mont Terri underground research laboratory (URL).

- A development programme to advance the knowledge base of non-intrusive monitoring based on seismic tomography.

- Preparation of the design of the PRACLAY seal steel support structure and selection of MX-80 bentonite as the swelling material to be used.

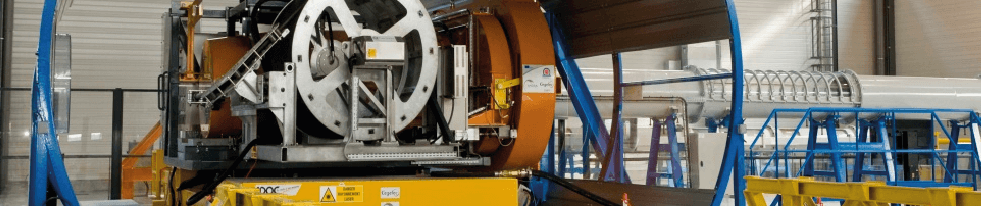

- Module 2, Transfer and Emplacement of Waste Canisters: Transport and emplacement systems for two different waste canister types (for vitrified waste: weight 2 tonnes and for spent fuel rods: weight 5.2 tonnes) were developed, fabricated and successfully tested in surface facilities. In addition, a Retrievability Desk Study was completed, which reviewed a number of existing designs for retrievable disposal.

- Module 3, Heavy Load Emplacement Technology: It was demonstrated that either air or water cushion technology can be used for the emplacement of long (more than 5m), heavy (up to 45 tonnes) waste containers that have a relatively small diameter (as small as 1.25m) in disposal drifts with a diameter only marginally bigger than the canisters. The same equipment is also capable of emplacing 17 tonne bentonite buffer ring packages (2.3m diameter), again with only minimal annular gap between the rings and the disposal drift wall.

- Module 4, Temporary Sealing (using low-pH cement) Technology: It was shown that shotcrete with a pH equal to or below 11, which is compatible with engineered barriers such as bentonite, can be formulated and used for the construction of plugs/seals in underground repositories.

The second objective of the ESDRED project was to promote a shared European vision in the field of radioactive waste disposal technology. ESDRED contributed to a shared European vision by providing a platform for a common research programme and facilitating the transfer of knowledge and experience between different national waste management organisations.

The third objective of the ESDRED project, training and communication, was addressed in Module 5. Activities undertaken to meet the training and communication objectives of the project included:

- Organising an international conference around ESDRED technology issues.

- Creating and maintaining an up-to-date web site.

- Organising university lectures for Masters level students and young graduates.

- Organising international workshops and contributing to international workshops organised by others.

- Preparing videos of the work for industrial and general public consumption.

- Participating at international conferences by presenting ESDRED papers and/or posters and, at times, chairing sessions.

- Publication of articles in technical journals.

- Preparing leaflets for the professional and the general public on specific parts of the project.

- Ensuring coverage of ESDRED activities within in-house publications/newsletters at the national agency and the research institute level, as well as with some of the ESDRED sub-contractors.

- Organising media events and related news releases around some of the demonstrators fabricated within ESDRED.

- Organising demonstrations of the equipment produced, to which various stakeholders were invited.

- Encouraging a secondment to an ESDRED-related fabrication project.

- Participating in other FP6 projects (COWAM 2) for increased exposure to other stakeholders and for confidence building.