DOPAS: Full scale Demonstration of Plugs and Seals

DOPAS aimed to improve knowledge of the industrial feasibility of plugs and seals for geological disposal facilities. It focused on the measurement of their characteristics, the control of their behaviour over time in repository conditions and their hydraulic performance.

Overview

Project Dates: 01/09/2012 – 31/08/2016

Project Status: Finished

Project website: https://www.posiva.fi/dopas/en/dopas.html

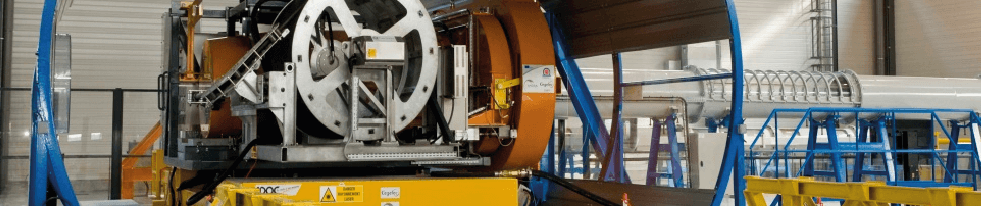

The DOPAS project addressed the design basis, reference designs and strategies to demonstrate the compliance of the reference designs to the design basis for plugs and seals in geological disposal facilities. The project focused on shaft seals for salt rock (German repository concept), tunnel plugs for clay rock (French and Swiss repository concepts), and tunnel plugs for crystalline rock (Czech, Finnish and Swedish repository concepts). Five different demonstration experiments were part of the project in Sweden, France, Finland, Czech Republic and Germany, each at different stages of development. The Swedish demonstrator was constructed prior to the start of the DOPAS project and provided experience on demonstration of compliance of the reference design to the design basis. The German demonstrator was installed after the DOPAS project started and focused on demonstration of suitability by performance assessment. The French, Finnish, Swedish, German and Czech experiments addressed developments in all phases of the design basis, reference designs and strategies to demonstrate compliance of the reference designs to the design basis. The studied concepts were developed in DOPAS’s five thematic scientific/technological work packages, which each integrated the results of the individual experiments.

The DOPAS project derived from the IGD-TP’s Strategic Research Agenda that points out the topic of “plug and seals” as a first priority issue for joint European RTD projects.

Objective

DOPAS aimed to improve overall understanding of using plugs and seals in geological disposal facilities. The project was divided into 7 work packages each with individual objectives.

Work package 1

Work package 1 focused on coordination and administration of the project. The main objectives of work package 1 were:

- to manage and coordinate the DOPAS project and provide project management coordination support to activities and to the DOPAS work in the different work packages;

- to steer and support the work package leaders and in the work package planning;

- to organise in cooperation with the IGD-TP Secretariat the project website and extranet and publish the public project results with open access on the public website;

- to act as an information and communication centre about the public activities of the DOPAS including a project website for open access and a restricted extranet;

- to collect and compile project management information of the DOPAS project to ensure compliance with the requirements set in the ECGA and the Consortium Agreement (CA) and organise for the distribution of EC financial contribution and for collecting audit certificates; and

- to provide means of quality assurance and control of project results.

Work package 2

Work package 2 focused on the design of the plugs and seals. The main objective of work package 2 was to develop the design basis for different plugs and seals describing explicitly the process and approach of coming to the design basis ‐ including transparency of the different national requirements and their comparison to explain the differences in the different experiments’ design basis envisaged in current consortium member’s repository systems for salt, clay and crystalline rock.

A further objective of WP2 was to describe the reference designs based on this design basis and elaborate the strategies for demonstrating the conformity of the reference designs to the design basis. There were four tasks in this work package focusing on the following geologies and experiments:

- Salt rock: plugs, seals and supporting elements (abutments) in mechanically excavated vertical shafts (ELSA experiment);

- Clay rock: plug and seal in mechanically excavated horizontal tunnel (FSS Experiment with Andra, Nagra); and

- Crystalline rock: plug and seal in drill-and-blast excavated horizontal tunnel (DOMPLU Experiment with SKB and Posiva; POPLU Experiment with Posiva, VTT, BTECH and SKB; and EPSP Experiment with RAWRA and CTU).

Work Package 3

Work package 3 focused on testing full scale models of plugs and seals. The objectives of work package 3 were:

- to (further) develop a comprehensive design basis for the in-situ demonstration experiments planned in the Czech Republic, Finland and France;

- to carry out large/full-scale tests (EPSP, FSS) in underground rock laboratories or mock-up drifts, and URCF ONKALO (POPLU), proving that the stated reference design, which is used as subsystem justification in the licence applications for the final repositories fulfils the requirements and can be implemented on an industrial scale;

- to monitor full-scale demonstration (DOMPLU) at Äspö HRL; and

- to address seal plug materials with respect to long-term behaviour, providing experimental data needed for numerical simulations in order to demonstrate material suitability.

Work package 4

Work package 4 focused on evaluating the designs specified in WP2 and tested in WP3. The objectives of work package 4 were to:

- assess and evaluate the construction methodologies and technologies for plugs and seals (WP3);

- assess and evaluate the results of the subsequent monitoring phase and the outcome of the dismantling activities to evaluate the predictions against the actual measured performance;

- summarise the achievements made in design and the industrial scale implementation construction, in the light of the specified required performance of plugs and seals as defined in Work Package 2; and

- to provide a basis and direct input for performance assessment related activities carried out in (WP5).

Work Package 5

Work package 5 focused on the long term performance of the plugs and seals with specific focus on improving modelling. The objectives of work package 5 were to:

- undertake process modelling of the experiments performed in WP3 to gain process understanding;

- identify the main processes that are relevant and thus to be considered for predicting the short and long-term behaviour of the plug and sealing systems;

- identify remaining uncertainties and their influence on performance assessment;

- develop and justify conceptual models of plugs and seals for the different disposal concepts and geological environments;

- simulate processes and their evolution within individual sealing components;

- further develop and apply the performance assessment methodology and (conservative) performance assessment models for analysing the system behaviour.

Work package 6

Work package 6 was a summation task which consolidated the project findings and produced the final report. Work package 6 also facilitated collaboration and knowledge exchange. The main objectives of work package 6 were:

- to review the project results by using EE method and ensure that the quality of the results are assured;

- to provide for expert staff site visits, learning from each other and to enhance the integration between experiments;

- to compile the lessons learned and experiences useful for implementing plugs and seals in various disposal concepts and highlighting the future open questions related to plugs and seals; and

- to produce the final public DOPAS project research report.

Work package 7

Work package 7 was for dissemination of results to the project members, the wider industry and the general public, primarily though reports. It also facilitated training programs and access to the experimental sites.