Publication of NWMO’s latest technical programme report and recognition of BEP Surface Technologies successful coating-copper services

27/11/2025

Canada’s waste management organisation, NWMO, has published its latest annual report on their technical programme for long-term management of Canada’s used nuclear fuel (available here or direct from their website). The report presents a summary of activities and progress in 2024 to develop the repository design to understand the engineered barrier, geological and other processes important to the safety case with a particular focus in assessing the two remaining siting areas. This effort culminated with the selection of the Revell site for the used fuel Deep Geological Repository (DGR) with the potential host communities Wabigoon Lake Ojibway Nation and the Township of Ignace agreeing to move forward into the regulatory approvals process. NWMO continued to participate in international research activities, including projects associated with the Posiva Encapsulation Plant for spent nuclear fuel, the Mont Terri Underground Rock Laboratory, the ONKALO facility, the Grimsel Test Site and the OECD Nuclear Energy Agency.

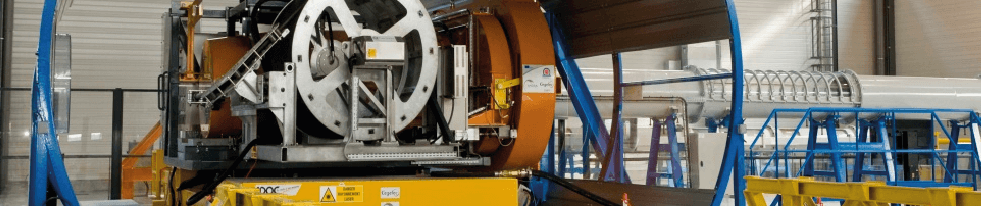

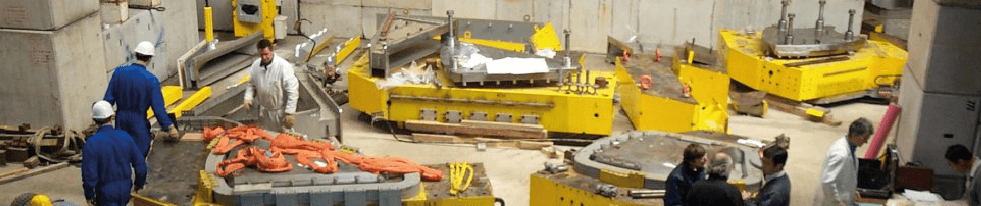

In the report, NWMO recognises one of our IGD-TP member organisations, BEP Surface Technologies (BEP), for provision of electrodeposition copper-coating services for the Mark II Used Fuel Container, a key safety barrier for the country’s future deep geological repository. BEP is a leading electroplating and surface finishing specialist, and has spent over a decade perfecting a specialised copper coating designed to protect nuclear waste containers for hundreds of thousands of years underground. Its copper-coated Mark II Lower Assembly and Hemi-Head components passed every inspection and high-tech scan by NWMO – these included visual and liquid penetrant (LP) methods, and advanced non-destructive examination (NDE) techniques (phased array ultrasonic testing (PAUT), eddy current testing (ECT)). The results indicated that all design requirements (bond, thickness) and quality characteristics (e.g., absence of volumetric and surface defects) were met within margin (e.g., no relevant indications or rejectable signals). This work, along with prior metallurgical qualification and demonstration, confirmed that BEP is fully qualified to supply electrodeposition copper-coating services to produce Mark II UFC shells, lower assemblies and hemi-head components. BEP’s full press release about this exciting achievement is available here.